AI – PREDICTIVE ANALYTICS

OPERA MES

AI – Predictive Analytics

Opera Intelligent MES. Intelligent Facilities

Artificial Intelligence and its evolution, particularly that of artificial neural networks, enables the designing, development and implementation of new methods and new data management and analysis systems, moving from a reactive approach to a proactive or predictive one.

The Opera platform integrates the use of AI, Deep Learning and ANN, applied to the field of manufacturing, to implement Intelligent Facilities.

Thus Opera allows you to go beyond standard real-time process monitoring and carry out predictive analytics on the big data that has been acquired and stored, giving it new value which will aid in preventing problems and guiding the factory to peak operational excellence.

BIG DATA, AI & ANN

Use of AI, Deep Learning and artificial neural networks to manage and process the big data acquired and stored by Opera MES.

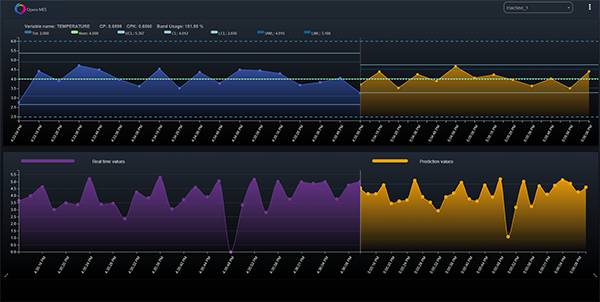

PREDICTIVE CONDITION MONITORING

Predictive monitoring of the conditions of an asset, with forecast of future values and generation of alarms regarding probable deviations.

PREDICTIVE MAINTENANCE

Predictive maintenance on assets. Predict when an asset will experience downtime, malfunction or breakage.

PREDICTIVE QUALITY

Predictive quality regarding the future values of test results. Anticipate possible non-conformities and eliminate product defects.

Key Features

- AI Integration (ANN)

- Predictive Condition Monitoring

- Predictive Maintenance

- Predictive Quality

HIGHLIGHTS

![]()

INTELLIGENT MES

![]()

DEEP LEARNING, AI, ANN

![]()

DATA SCIENCE

![]()